Screws vs Threads

Why Most OAGs Are Connected with Screws Instead of Threads

Most Off-Axis Guiders (OAGs) are designed to be bolted to a filter wheel, a filter drawer or an adapter, on the camera side rather than attached via threaded connections. This is intentional and important for several reasons:

Precise Prism Alignment

The prism inside the OAG must be carefully positioned relative to the primary sensor, capturing light from just outside the optical axis without casting a shadow on the image.

Bolting the OAG ensures that the prism is always in the correct orientation relative to the primary camera sensor.

Threaded connections rotate the OAG as you tighten, making the final prism position unpredictable.

Mechanical Stability

Bolt connections create a rigid, flexure-free assembly between the OAG and the camera.

Threaded connections can introduce slight mechanical play or loosening over time, especially as temperature changes during a night of imaging.

Repeatable and Reliable Setup

With bolts, you can always reinstall the OAG in the exact same position after disassembly or maintenance.

Threading cannot guarantee repeatable alignment, leading to variations in guiding performance.

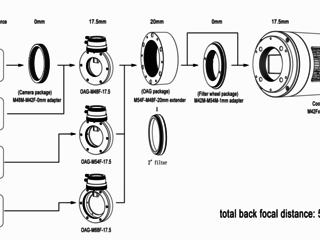

Optimized Backfocus Control

Bolting allows the OAG to sit in the correct optical train spacing without introducing unnecessary thread length, which could impact the required backfocus distance.

Many camera and filter wheel manufacturers design their mounting plates specifically to bolt OAGs at the correct optical spacing.

Note:

For flexibility, some OAGs include a 20mm adapter with an internal M48x0.75 thread, allowing you to connect the OAG to a camera with a threaded interface if needed.

However, for best performance, especially when guiding precision is critical, we recommend bolting the OAG directly whenever possible.

Always check the product information to determine whether a 20mm adapter/spacer is included.