OGMA Universal Filter Drawer (UFD) for Off-axis Guider (OAG)

Unlike most filter drawers, the OGMA UFD allows the precise positioning of an Off-Axis Guider, ensuring optimal performance and ease of use.

What sets the OGMA UFD apart is its versatility. You can connect it to a wide array of cameras either by using screws on both sides or the large thread around the center.

You can download 3D-printing models of the drawer to accommodate filters of different sizes and threads.

The OGMA UFD adapts to your specific astrophotography needs now and in the future.

PROMO: Get 50% OFF when you buy this filter drawer with a cooled IMX571 or IMX585 camera.

Discounts will show in your cart while supplies last.

Highlights

When using an OAG, it's crucial to position the OAG's prism exactly above the camera sensor. Traditional filter drawers often pose a challenge in predicting the final prism position of an OAG because they are connected to the imaging train using a large thread at the center. While tightening the tread, it is hard to know the final position of the prism.

This OGMA UFD can be connected using screws that are precisely placed to make sure that the prism of the OAG will fall at the required angle, consistently—no more guessing where the prism will be after tightening the threads.

Compatibility

This is a preliminary list:

- All cooled OGMA cameras

- Most cooled cameras from Touptek

- Most cooled ZWO cameras featuring six M2.5 screw holes distributed around a 62mm circumference on the front face around the sensor

- Some Player One cameras

We will continue expanding this list.

Back Focus Considerations

This product can take either 20mm or 21mm of back focus.

The main body of the UFD has a width of 20mm.

We include a thread adapter/extender that adds 1mm of back focus and adapts the tread from M54 (F) to M48 (F).

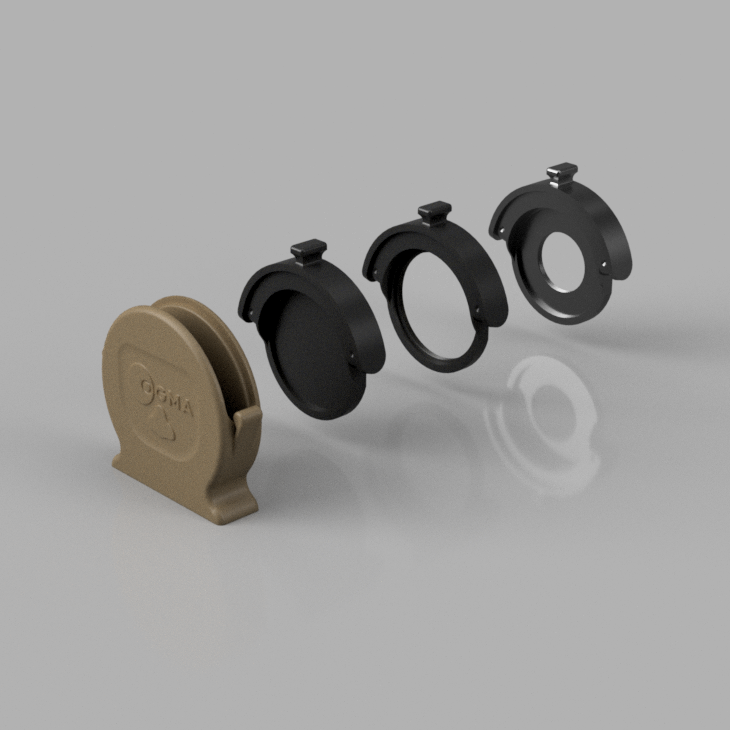

What's in the Box?

20mm wide body of the filter drawer with M54 (F) threads on both sides

Aluminum drawer for 2-inch mounted filters with M48 (F) thread

1mm extender with M54 (M) and M48 (F) - used to increase the total width of the filter drawer

Thread adapter M54 (M) and M48 (F)

Multiple screws

Two Allen keys

Need more drawers?

OGMA's Universal Filter Drawer gives you unmatched flexibility to adapt your setup to any filter size or shape you need. We provide 3D models of our drawers, allowing you to 3D print extras or modify them to fit your specific filters. But if you prefer a precision-machined option and don't mind the extra cost, you can also purchase additional CNC-crafted drawers.

Warranty

OGMA warrants your product to be free from defects in materials and workmanship for one year. OGMA will repair or replace a product or part which, upon inspection by OGMA, is found to be defective during one year following the date that you receive the equipment.

For specific details, read OGMA's limited warranty.